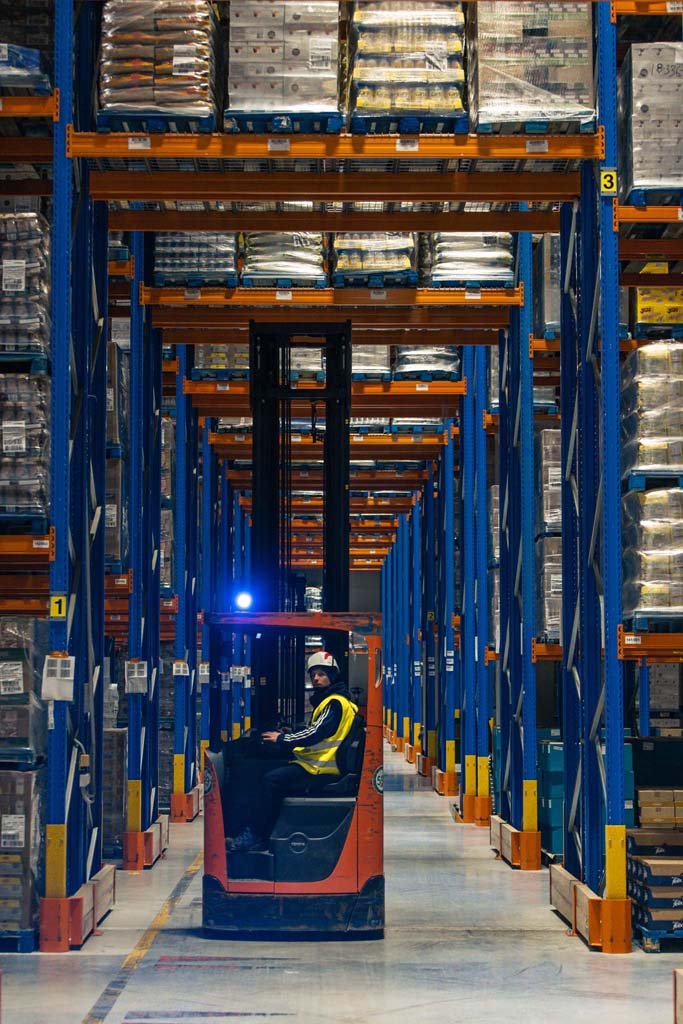

Did you know that our warehouses span a total of 517,000 m² across 14 branches strategically located throughout Central and Eastern Europe? In the Czech Republic alone, we can store up to 180,000 pallets, with around 15,000 shipped out every day. And that’s just the beginning — our facilities in Slovakia, Poland, Hungary, and Romania are just as impressive. Learn more about what makes our warehouses unique and why they stand out on the European logistics market.

At the heart of all our logistics operations are our warehouses, located across five countries in Central and Eastern Europe. These facilities enable us to offer comprehensive storage services that meet the needs of large clients such as Nestlé and Tesco, as well as medium-sized and smaller businesses.

We are experts in the storage and transportation of goods that require specific temperature conditions. We can handle a wide range of dry, chilled, and frozen goods, providing storage across all temperature regimes from +25 °C to -25 °C..

For products that do not require special temperature conditions, we offer dry storage, also known as ambient storage. This type of storage is ideal for most consumer and industrial goods..

Products such as fresh food and certain pharmaceutical items often require storage at specific (low) temperature. For these, we offer chilled storage in a precise and controlled temperature range, ensuring the freshness and quality of the goods throughout the entire storage period.

Frozen product storage requires strictly controlled temperature conditions (typically between -18°C and -25°C), which we are fully equipped to provide in our warehouses. We typically store frozen foods, frozen meat, fish, vegetables, and frozen baked goods this way. In addition, our freezing warehouses are equipped with modern sensors and technologies for monitoring temperature and humidity, allowing us to continuously ensure that the ideal conditions are consistently maintained.

Our customs and tax warehouses are designed to facilitate the storage and distribution of goods subject to customs and tax regulations. They can be used, for example, to store goods awaiting customs clearance or those taxed only after order picking. The transportation and inventory of such goods are also under strict supervision by the Customs Office.

We use the cross-docking service for direct transfer of goods from one vehicle to another, without storing them in our facilities. Distribution routes cannot always be planned directly, which is why we use this option to accelerate and streamline the distribution of goods that cannot be stored for long, such as fresh food.

We also offer our clients a wide range of value-added services (VAS). These are essentially completion processes that save our clients time, effort, and resources. In addition to co-packing, labeling, and carton mixing, we can also handle filling promotional displays, inkjet printing, and gift or holiday packaging.

We use the latest technologies in our warehouses, allowing us to adapt to our clients’ needs and process orders more efficiently and quickly. And because we understand our role in environmental protection, we take sustainability into account when planning our warehousing solutions.

In our warehouses, we use advanced Warehouse Management Systems (WMS) based on SAP software, which has been developed and programmed with our specific needs in mind.

To optimize all warehouse processes, we use online monitoring of warehouse operations, enabling us to efficiently manage, monitor, and retrospectively check all individual actions. We also operate in a paperless mode using barcode scanners instead.

To improve the efficiency of our warehouse processes, we have implemented modern automation technologies in our distribution centers. These allow all goods handling, sorting, and distribution to be done faster and error-free, while our people can focus on more demanding tasks.

At Hopi, we place great emphasis on sustainability and eco-friendly initiatives, and our warehouses are a testament to this. They are designed to contribute to minimizing negative environmental impact and reducing energy consumption. You’ll find specific strategies and measures we use further in the article.

It's no coincidence that some of the largest companies on the European market trust us with warehousing, transport, and other services. Working with us offers a range of advantages that have made Hopi Logistics synonymous with reliability in the logistics world.

Our 14 logistics centers are strategically located across five Central and Eastern European countries. This allows us to provide fast, efficient, and reliable logistics solutions across the entire region.

We also focus on quality, and our distribution centers are designed to accommodate both short-term storage and cross-docking and complex logistics operations, including fulfillment services. We can thus provide our clients with comprehensive e-commerce solutions across Central and Eastern European markets.

We offer flexible storage capacities that allow us to easily adapt to changes in goods volume, seasonal fluctuations, and specific storage requirements. Our warehouses are designed to be easily adaptable to various client needs. We can quickly respond to changes without compromising the quality or efficiency of our processes.

Our logistics solutions owe their success first and foremost to our people. Thanks to our team of specialists, backed by years of experience in managing logistics and warehouse operations, we run logistics centers and transport with efficiency and quality that set industry standards.

We work tirelessly to turn our logistics center employees into true experts. We offer performance-based rewards, training opportunities, and career growth.

Thanks to our extensive storage facilities, we can accommodate large volumes of goods and ensure highly specific and strict storage conditions. That’s why our clients include some of the biggest players on the market, across various industries.

The food industry is one area where maintaining product freshness and quality is absolutely crucial. We store and transport products like dairy, meat, fruits, and vegetables in controlled-temperature environments to ensure they remain fresh and safe to consume. We use the FEFO strategy, shipping goods based on expiry dates (except for wine, which we manage by batch).

If there’s one sector where strict conditions are a matter of life and death, it’s pharmaceuticals. Pharmaceutical products, including medicines, vaccines, and lab samples, can be extremely temperature-sensitive, which is why clients trust us with their storage. In our specially designed and constantly monitored cooling facilities, we guarantee stable temperatures and hygienic conditions that meet all safety standards for storing pharmaceutical products.

Storing consumer and retail non-food goods requires flexibility and speed to help our clients deliver products to end customers on time and in perfect condition. That’s why we focus on effective inventory management and supply chain optimization to keep up with the demands of the fast-paced retail market.

We pride ourselves on quality, safety, and transparency across all our operations, from product storage to employee workplace safety. This is reflected in the numerous certifications we hold.

We hold multiple ISO certifications that confirm we operate in accordance with international standards of quality, safety, and efficiency. These include ISO 9001 for quality management and customer satisfaction, ISO 14001 for environmental management, ISO 45001 for occupational health and safety, and ISO 50001 for energy efficiency.

In our logistics operations, we use the HACCP system, which focuses on identifying and addressing food safety risks. This enables us to ensure a high level of hygiene and safety during storage (and of course also transport and handling) of goods.

The IFS Logistics certification confirms our ability to maintain high quality standards throughout all our logistics operations, especially when it comes to food and goods that require specific storage conditions.

We consider it important to contribute to environmental protection and minimize the potential negative effects our activities may have by nature. In line with our values, we also support local communities and meaningful projects that, in our view, make the world a better place.

In our Czech warehouses, we have successfully reduced CO2 emissions by 13.18% compared to 2021. By 2025, we aim to reduce Scope 1 and 2 emissions by 10% per square meter of warehouse space compared to the base year 2021.

Additionally, we reduce waste and packaging by sorting and recycling waste and using energy-efficient packaging machines. We also recycle old appliances and plant one tree for every 10 cartons of paper we use.

Our warehouses are designed for maximum energy efficiency, which helps reduce not only costs but especially environmental impact. Measures we’ve implemented include:

We are involved in numerous projects that contribute to improvements both locally and more broadly. In the Czech Republic, for example, we support the annual Ride of the Kings in Vlčnov, the Faculty of Business Administration at the University of Economics, research by the Czech Institute of Egyptology, education in the Central African Republic, and one-time projects and renovations of cultural or educational buildings.

Do you have a question or want a tailored logistics solution? We're happy to help!

Do you have a question about our services in the Czech Republic or Central Europe? Contact our specialists, who will be happy to advise you and help find a solution that meets your expectations.

Interested in our services? Fill out our inquiry form and we’ll get in touch with you.