Frozen logistics is one of the most demanding areas of the supply chain. It requires absolute precision, a high level of technological advancement, and maximum reliability at every stage—from storage to distribution. At HOPI Logistics, we have transformed this field over the past 33 years into a highly efficient and innovative system that now serves key markets across Central and Eastern Europe.

In our recent webinar, we presented what modern frozen logistics looks like in practice – including technologies, process management, approach to sustainability, and onboarding of new customers.

HOPI Supply Chain now operates in more than 7 countries across Central and Eastern Europe. In the frozen logistics sector, we focus especially on the Czech Republic, Slovakia, and Hungary, where we operate central freezing warehouses with a capacity of over 65,000 pallet places.

Each warehouse is designed for different types of pallets (including atypical ones) and features highly durable equipment capable of handling temperatures from –25 to +25 °C. Warehouse processes are managed using a system built on SAP, which ensures high accuracy, traceability, and efficient capacity planning.

We ensure frozen distribution through our own fleet of 350 units. The vehicles are equipped with cooling units and adapted to various types of cargo – from small delivery vehicles to roadtrain combinations.

We base our distribution on a combination of central hubs and regional centers. As part of so-called city logistics, we plan to expand the fleet with smaller electric vehicles for delivering smaller volumes directly to city centers and smaller outlets.

Beyond standard logistics services, we offer:

Thanks to our integration with Hopi Food, we can ensure complete food processing, including repackaging and dispatch in the required format.

We integrate eco-friendly technologies into our warehousing and transport operations:

Our goal is to reduce emissions by 30% by 2030 and by 95% by 2050. More about our sustainability approach.

Technology and flexibility go hand in hand with us. Within the Hopi Innovation Lab we are testing:

Our development team has over 30 specialists who tailor the system to customer needs – including integrations and data exchanges.

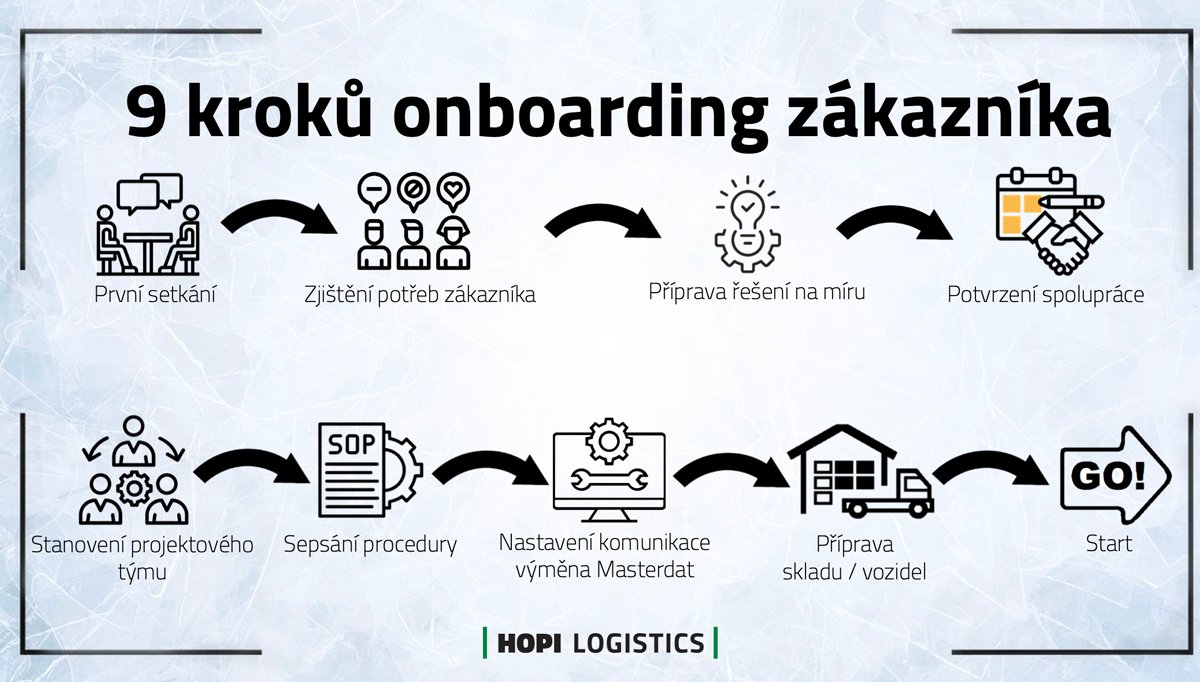

Every new customer goes through a standardized onboarding process, which includes:

Our goal is for the cooperation to run smoothly from the start without the need for excessive client-side preparation.

Frozen logistics at HOPI is built on stable infrastructure, thorough process control, and advanced technologies. We are ready to offer you tailored solutions – whether you're looking for warehousing, distribution, or value-added services in the frozen, chilled, or dry goods sector.

Interested in what a partnership with HOPI Logistics could look like for your business? Contact us. We’ll be happy to meet with you.